Digital Fiber Sensor FX-250

Download

-

Basic Information

-

Order guide

-

Option

-

Specifications

-

Dimensions

-

Circuit / Wiring

-

List of fibers

-

Cautions For Use

Basic Information

“Ease of use” evolves to the next generation.

Features

Overwhelmingly easy to understand, Organic EL display

The clear, high-visibility flat panel ensures easy operation to reduce setting time and minimize setting errors. It contributes to improved efficiency on the production site.

Enables intuitive operation without referring to the manual

[Reduces setting time] [Minimizes setting errors]

Compact body

The compact body can be easily mounted to small equipment and robotic hands with limited installation spaces.

[New function] Smart limit teaching

Simultaneous execution of teaching and circumvention of saturation

Teaching is executed only with two pushes of a button, and this also achieves circumvention of saturation simultaneously.

There is no need for separate adjustment of the light emission amount, thus contributing to reduction of setting man-hours.

* Only when limit teaching is used

Incident light intensity adjustable in 100 increments

The incident light intensity can be varied in 100 steps to allow flexible and precise adjustment of incident light intensity even when the incident light becomes saturated due to installation in a close distance or during detection of a transparent or very small workpiece, thus realizing stable detection.

Detection of metal wire

Detection of transparent sticker on transparent sheet

Alternate frequency interference prevention function

In the case the fibers are arranged side by side, mutual interference can be prevented by setting different light emission frequencies (4 settings).

* Response time varies depending on light emission frequencies.

* When the alternate frequency interference prevention function is used, up to four fiber head units can be mounted in contact with each other.

Zero-set function

When a reflective type fiber is used, offsetting the incident light intensity to "0" with no workpiece present enables confirmation of only the change caused by the detected object.

When multiple amplifiers are mounted side by side, all displayed values can be set to "0."

Equipped with three types of timer function

A variety of timer control operations can be carried out only by fiber sensors.

Timer period setting range: 1 to 9,999 ms, in 1-ms increments (default setting: 1 ms)

Display and indicator can be set to OFF.

Since the digital display and large output indicator can stay turned off during use, the FX-250 series is suitable for use with equipment that can be affected by light or heat.

Stable detection over long periods and short periods

Stabilization of light emission amount

The built-in APC circuit stabilizes the short-time fluctuation of the light emission amount at the time of power on and the four-element light emitting diode ensures stable emission over long periods.

■ APC circuit

When power is turned on or when the temperature changes, the sensor's light emission amount fluctuates and causes instability of output. To solve this problem, the APC circuit controls the light emission amount to ensure short-term emission stability.

■ Four-element light emitting diode

When a conventional LED operates for a long period of time, the LED becomes damaged due to heat or the light intensity decreases due to oxidation. The four-element light emitting diode suppresses degradation of the light emitting element to the maximum extent and ensures long-term emission stability.

Order guide

Amplifier

| Appearance | Model No. | Emitting elemen | Output |

|---|---|---|---|

| FX-251-C2 | Red LED | NPN open-collector transistor |

| FX-251P-C2 | PNP open-collector transistor |

End plates

End plates are not supplied with the amplifier. Please order them separately when the amplifiers are mounted in cascade.

| Appearance | Model No. | Description |

|---|---|---|

| MS-DIN-E | When an amplifier moves depending on the way it is installed on a DIN rail, these end plates clamp amplifiers into place on both sides. Make sure to use end plates when connecting multiple amplifiers together. [Two pcs. per set] |

Option

| Designation | Model No. | Description |

|---|---|---|

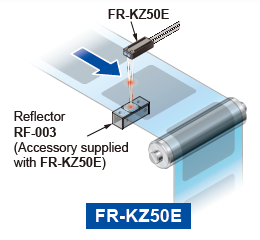

| Amplifier mounting bracket | MS-DIN-2 | Mounting bracket for amplifier |

Amplifier mounting bracket

MS-DIN-2

Others

Please refer to "Fiber Options" for details of fiber lenses and other options.

Specifications

| Type | NPN output type | PNP output type | |

|---|---|---|---|

| Model No. | FX-251-C2 | FX-251P-C2 | |

| Applicable regulations | CE Marking (EMC Directive, RoHS Directive) | ||

| Supply voltage | 12 to 24 V DC ±10% Ripple P-P 10% or less | ||

| Power consumption | 960 mW or less (current consumption 40 mA or less at 24 V supply voltage) | ||

| Output | NPN open-collector transistor ・Maximum sink current: 100 mA ・Applied voltage: 30 V DC or less (between output and 0 V) ・Residual voltage: 2 V or less (at maximum sink current) | PNP open-collector transistor ・Maximum source current: 100 mA ・Applied voltage: 30 V DC or less (between output and +V) ・Residual voltage: 2 V or less (at maximum source current) | |

| Output operation | Switchable either Light-ON or Dark-ON | ||

| Short-circuit protection | Incorporated | ||

| Response time | H-SPD: 35 μs or less, FAST: 60 μs or less, STD: 250 μs or less, LONG: 2 ms or less, H-PWR: 24 ms or less, selectable | ||

| Output indicator | Orange LED turns on when output is ON. | ||

| Sensitivity setting | 2-point teaching / Limit teaching / Full-auto teaching / Manual adjustment | ||

| Threshold value adjustment function | Incorporated | ||

| Incident light intensity adjustment function | Incorporated, max. 100 steps | ||

| Incident light intensity display range | H-SPD / FAST / STD: 0 to 4,000, LONG / H-PWR: 0 to 9,999 | ||

| Digital display | White organic EL display | ||

| Various settings | Shift amount setting (percentage, fixed value), display style setting, display inversion setting, ECO setting, zero-set function | ||

| Timer function | OFF-delay timer / ON-delay timer / One-shot timer, switchable either effective or ineffective (setting range: 1 to 9,999 ms in 1-ms increments) | ||

| Interference prevention function | Incorporated (4 selectable frequencies) (Note 2) | ||

| Environmental resistance | Protection | IP40 (IEC) | |

| Ambient temperature | -10 to +55 ℃ +14 to +131 ℉ (If 4 to 7 units close mounting: -10 to +50 ℃ +14 to +122 ℉ or if 8 to 16 units close mounting: -10 to +45 ℃ +14 to +113 ℉) (No dew condensation or icing allowed), Storage: -20 to +70 ℃ -4 to +158 ℉ | ||

| Ambient humidity | 35 to 85% RH, Storage: 35 to 85% RH | ||

| Ambient illuminance | Incandescent light: 10,000 ℓx or less at the light-receiving face | ||

| Voltage withstandability | 1,000 V AC for one min. between all supply terminals connected together and enclosure (Note 3) | ||

| Insulation resistance | 20 MΩ or more, with 250 V DC megger between all supply terminals connected together and enclosure (Note 3) | ||

| Vibration resistance | 10 to 150 Hz frequency, 0.75 mm 0.030 in double amplitude (100 m/s2 max.) in X, Y and Z directions for two hours each (without power supply) | ||

| Shock resistance | 98 m/s2 acceleration (10 G approx.) in X, Y and Z directions five times each (without power supply) | ||

| Emitting element (modulation type) | Red LED (Peak emission wavelength: 660 nm 0.026 mil) | ||

| Material | Enclosure, cover, switch: Polycarbonate | ||

| Cable | 0.2 mm2 3-core cabtyre cable, 2 m 6.562 ft long | ||

| Cable extension | Extension up to total 100 m 328.084 ft is possible with 0.3 mm2, or more, cable. (however, supply voltage 24 V DC or more) | ||

| Weight | Net weight: 55 g approx., Gross weight: 80 g approx. | ||

Notes:

1) Where measurement conditions have not been specified precisely, the conditions used were an ambient temperature of +23 ℃ +73.4 ℉.

2) When the interference prevention function is used, set different light emission frequencies in the amplifiers for interference prevention.

3) The indicated voltage withstandability and insulation resistance values apply to the amplifier unit.

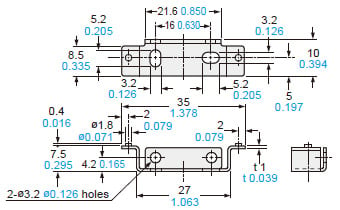

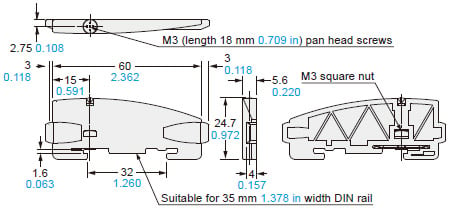

Dimensions

- Unit: mm in

FX-251-C2 FX-251P-C2

Amplifier

MS-DIN-2

Amplifier mounting bracket (Optional)

Material: Cold rolled carbon steel (SPCC) (Uni-chrome plated)

MS-DIN-E

End plate (Optional)

Material: Polycarbonate

Circuit / Wiring

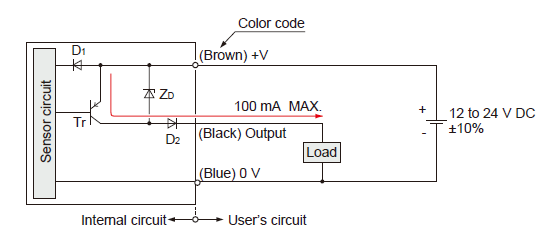

FX-251-C2

I/O circuit diagram

Symbols…

D1:Reverse supply polarity protection diode

D2:Reverse output polarity protection diode

ZD:Surge absorption zener diode

Tr:NPN output transistor

Wiring diagram

FX-251P-C2

I/O circuit diagram

Symbols…

D1:Reverse supply polarity protection diode

D2:Reverse output polarity protection diode

ZD:Surge absorption zener diode

Tr:PNP output transistor

Wiring diagram

Sensing characteristic

Sensing characteristics can be downloaded at catalog download site.

Please contact our office if not listed here.

Cautions For Use

- This website is a guide to select a suitable product. Be sure to read instruction manual of the product prior to its use.

- Never use this product as a sensing device for personnel protection.

- In case of using sensing devices for personnel protection, use products which meet laws and standards, such as OSHA, ANSI or IEC etc., for personnel protection applicable in each region or country.

Wiring

- Make sure that the power supply is OFF while adding or removing the amplifiers.

- Note that if a voltage exceeding the rated range is applied, or if an AC power supply is directly connected, the product may get burnt or damaged.

- Note that short-circuit of the load or wrong wiring may burn or damage the product.

- Do not run the wires together with high-voltage lines or power lines, or put them in the same raceway. This can cause malfunction due to induction.

- Verify that the supply voltage variation is within the rating.

- If power is supplied from a commercial switching regulator, ensure that the frame ground (F.G.) terminal of the power supply is connected to an actual ground.

- In case noise generating equipment (switching regulator, inverter motor, etc.) is used in the vicinity of this product, connect the frame ground (F.G.) terminal of the equipment to an actual ground.

Others

- This product has been developed / produced for industrial use only.

- The specification may not be satisfied in a strong magnetic field.

- Do not use during the initial transient time (the following time) after the power supply is switched ON.

H-SPD, FAST, STD: 0.5 sec., LONG, H-PWR: 1 sec. - These sensors are only for indoor use.

- Avoid dust, dirt, and steam.

- Make sure that the product does not come in contact with oil, grease, organic solvents such as thinner, etc., strong acid or alkaline.

- This product cannot be used in an environment containing inflammable or explosive gases.

- Never disassemble or modify this product.

- This product adopts EEPROM. Settings cannot be done a million times or more because of the EEPROM’s lifetime.

- The power input must meet the following requirements:

1. Be certified for its region of use

2. Have an output hold time of at least 20 ms

3. Have a rated output voltage of 12 to 24 V DC ±10% ripple P-P 10% or less and a current capacity of 0.5 A or more

4. If CE marking compliance is required, have SELV (Safety Extra Low Voltage)/PELV (Protective Extra Low Voltage) in accordance with the EMC Directive